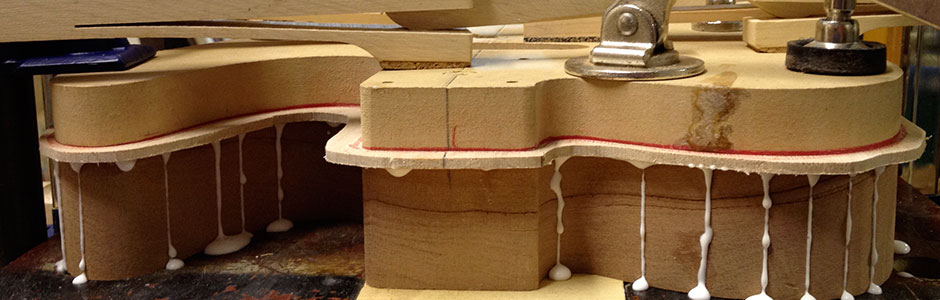

So we've successfully bent the rims and we're ready to glue them up to make the rims/sides structure. The two sides meet at the neck join area (aka "heel") and at the bottom (aka "tail"). They are overlength and are put into the mold to mark the correct lengths. Then they are sawed just outside this line. I used the band saw in this instance. Then the ends are nibbled away with a hand plane. In the photo below you see a little fixture that holds the sides to easily trim the work to a 90-degree angle to the top edge. There are four edges to clean up with the plane.

The first piece to glue Read more [...]

So we've successfully bent the rims and we're ready to glue them up to make the rims/sides structure. The two sides meet at the neck join area (aka "heel") and at the bottom (aka "tail"). They are overlength and are put into the mold to mark the correct lengths. Then they are sawed just outside this line. I used the band saw in this instance. Then the ends are nibbled away with a hand plane. In the photo below you see a little fixture that holds the sides to easily trim the work to a 90-degree angle to the top edge. There are four edges to clean up with the plane.

The first piece to glue Read more [...] Making the rims, part one: sides, neck block and tail block

Reply

So we've successfully bent the rims and we're ready to glue them up to make the rims/sides structure. The two sides meet at the neck join area (aka "heel") and at the bottom (aka "tail"). They are overlength and are put into the mold to mark the correct lengths. Then they are sawed just outside this line. I used the band saw in this instance. Then the ends are nibbled away with a hand plane. In the photo below you see a little fixture that holds the sides to easily trim the work to a 90-degree angle to the top edge. There are four edges to clean up with the plane.

The first piece to glue Read more [...]

So we've successfully bent the rims and we're ready to glue them up to make the rims/sides structure. The two sides meet at the neck join area (aka "heel") and at the bottom (aka "tail"). They are overlength and are put into the mold to mark the correct lengths. Then they are sawed just outside this line. I used the band saw in this instance. Then the ends are nibbled away with a hand plane. In the photo below you see a little fixture that holds the sides to easily trim the work to a 90-degree angle to the top edge. There are four edges to clean up with the plane.

The first piece to glue Read more [...]

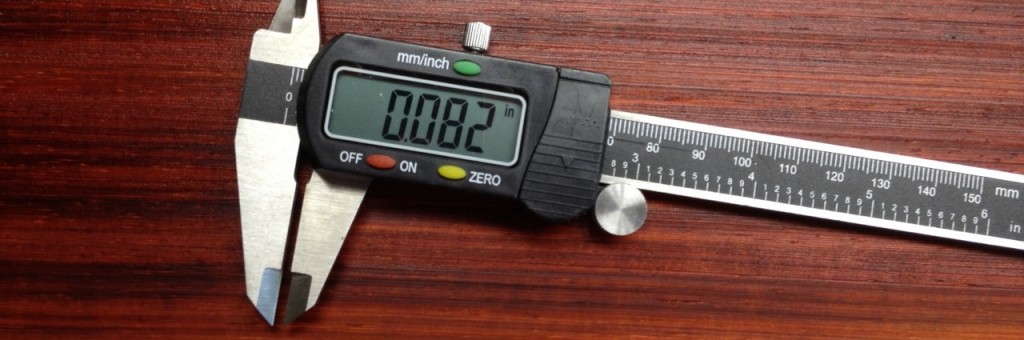

The sides come from your luthier supply house in the form of two slats, about 5 inches wide by 32 inches long and around 1/8 inch thick. I sand these down to about 0.085 inches with my drum sander before bending. Before I got that marvelous thing I had to reduce every board to useable thickness with a hand plane. Hand planes are great tools in the hands of great craftsmen. In my experience it's a little different; they do the job fine, right up to the point that I think I'm almost done, and then, yep, the blade slips a half-hair and digs into the board and ruins it. One day I thought, "Life's too

The sides come from your luthier supply house in the form of two slats, about 5 inches wide by 32 inches long and around 1/8 inch thick. I sand these down to about 0.085 inches with my drum sander before bending. Before I got that marvelous thing I had to reduce every board to useable thickness with a hand plane. Hand planes are great tools in the hands of great craftsmen. In my experience it's a little different; they do the job fine, right up to the point that I think I'm almost done, and then, yep, the blade slips a half-hair and digs into the board and ruins it. One day I thought, "Life's too