The linings, sometimes called "kerfings" or more properly "kerfed linings," are strips of wood that provide gluing surface for the top and sides joint. Traditionally, in steel-string guitars, the linings are 1/4-inch by 5/8-inch triangular mahogany strips with saw cuts (kerfs) that go almost through the strip to allow the flexibility to follow the curve of the sides. Read more [...]

The linings, sometimes called "kerfings" or more properly "kerfed linings," are strips of wood that provide gluing surface for the top and sides joint. Traditionally, in steel-string guitars, the linings are 1/4-inch by 5/8-inch triangular mahogany strips with saw cuts (kerfs) that go almost through the strip to allow the flexibility to follow the curve of the sides. Read more [...] Making the rims, part two: solid linings and a soundport

Reply

The linings, sometimes called "kerfings" or more properly "kerfed linings," are strips of wood that provide gluing surface for the top and sides joint. Traditionally, in steel-string guitars, the linings are 1/4-inch by 5/8-inch triangular mahogany strips with saw cuts (kerfs) that go almost through the strip to allow the flexibility to follow the curve of the sides. Read more [...]

The linings, sometimes called "kerfings" or more properly "kerfed linings," are strips of wood that provide gluing surface for the top and sides joint. Traditionally, in steel-string guitars, the linings are 1/4-inch by 5/8-inch triangular mahogany strips with saw cuts (kerfs) that go almost through the strip to allow the flexibility to follow the curve of the sides. Read more [...]

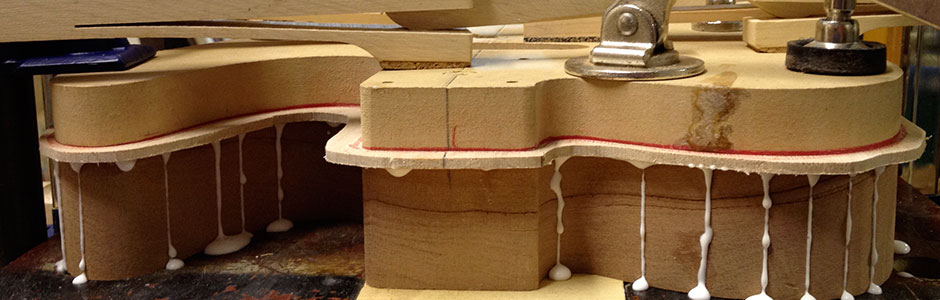

So we've successfully bent the rims and we're ready to glue them up to make the rims/sides structure. The two sides meet at the neck join area (aka "heel") and at the bottom (aka "tail"). They are overlength and are put into the mold to mark the correct lengths. Then they are sawed just outside this line. I used the band saw in this instance. Then the ends are nibbled away with a hand plane. In the photo below you see a little fixture that holds the sides to easily trim the work to a 90-degree angle to the top edge. There are four edges to clean up with the plane.

The first piece to glue

So we've successfully bent the rims and we're ready to glue them up to make the rims/sides structure. The two sides meet at the neck join area (aka "heel") and at the bottom (aka "tail"). They are overlength and are put into the mold to mark the correct lengths. Then they are sawed just outside this line. I used the band saw in this instance. Then the ends are nibbled away with a hand plane. In the photo below you see a little fixture that holds the sides to easily trim the work to a 90-degree angle to the top edge. There are four edges to clean up with the plane.

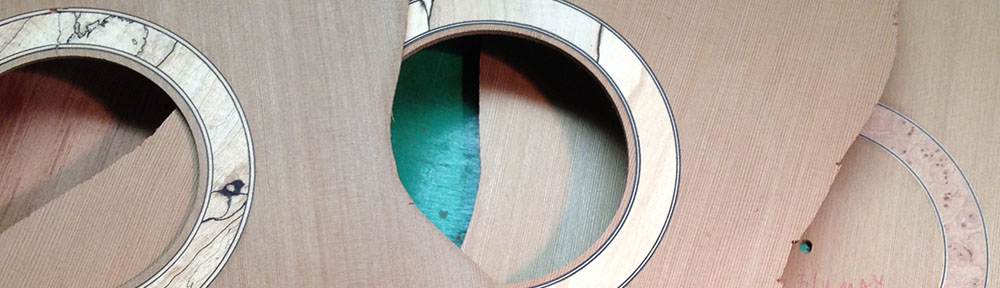

The first piece to glue  The top, or soundboard, is the most important contributor to the sound of the guitar. The critical factors seem to be that the top wood is stiff, yet light, and able to transmit sound without absorbing all of the sound energy. Traditionally, spruces are used due to their very high stiffness-to-weight ratios. And their ability to transmit sound quickly from end to end, their velocity.

Some woods soak up sound and produce a dull thud when stuck. This is damping, which has uses in lutherie, but not for top woods. Other woods are resonant, crisp, and ring with a "bell-like" tone. The longer the

The top, or soundboard, is the most important contributor to the sound of the guitar. The critical factors seem to be that the top wood is stiff, yet light, and able to transmit sound without absorbing all of the sound energy. Traditionally, spruces are used due to their very high stiffness-to-weight ratios. And their ability to transmit sound quickly from end to end, their velocity.

Some woods soak up sound and produce a dull thud when stuck. This is damping, which has uses in lutherie, but not for top woods. Other woods are resonant, crisp, and ring with a "bell-like" tone. The longer the