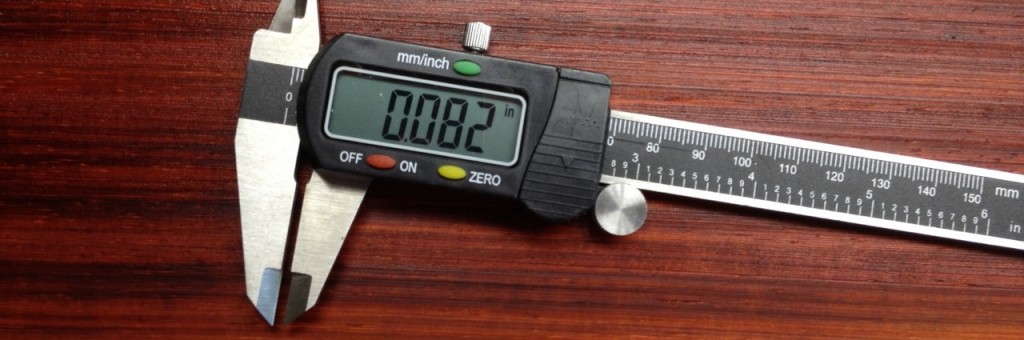

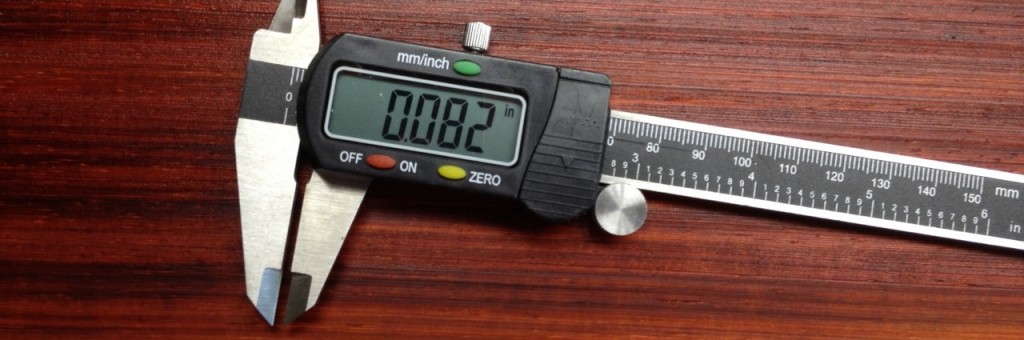

The sides come from your luthier supply house in the form of two slats, about 5 inches wide by 32 inches long and around 1/8 inch thick. I sand these down to about 0.085 inches with my drum sander before bending. Before I got that marvelous thing I had to reduce every board to useable thickness with a hand plane. Hand planes are great tools in the hands of great craftsmen. In my experience it's a little different; they do the job fine, right up to the point that I think I'm almost done, and then, yep, the blade slips a half-hair and digs into the board and ruins it. One day I thought, "Life's too Read more [...]

The sides come from your luthier supply house in the form of two slats, about 5 inches wide by 32 inches long and around 1/8 inch thick. I sand these down to about 0.085 inches with my drum sander before bending. Before I got that marvelous thing I had to reduce every board to useable thickness with a hand plane. Hand planes are great tools in the hands of great craftsmen. In my experience it's a little different; they do the job fine, right up to the point that I think I'm almost done, and then, yep, the blade slips a half-hair and digs into the board and ruins it. One day I thought, "Life's too Read more [...] Bending the sides

Reply

The sides come from your luthier supply house in the form of two slats, about 5 inches wide by 32 inches long and around 1/8 inch thick. I sand these down to about 0.085 inches with my drum sander before bending. Before I got that marvelous thing I had to reduce every board to useable thickness with a hand plane. Hand planes are great tools in the hands of great craftsmen. In my experience it's a little different; they do the job fine, right up to the point that I think I'm almost done, and then, yep, the blade slips a half-hair and digs into the board and ruins it. One day I thought, "Life's too Read more [...]

The sides come from your luthier supply house in the form of two slats, about 5 inches wide by 32 inches long and around 1/8 inch thick. I sand these down to about 0.085 inches with my drum sander before bending. Before I got that marvelous thing I had to reduce every board to useable thickness with a hand plane. Hand planes are great tools in the hands of great craftsmen. In my experience it's a little different; they do the job fine, right up to the point that I think I'm almost done, and then, yep, the blade slips a half-hair and digs into the board and ruins it. One day I thought, "Life's too Read more [...]

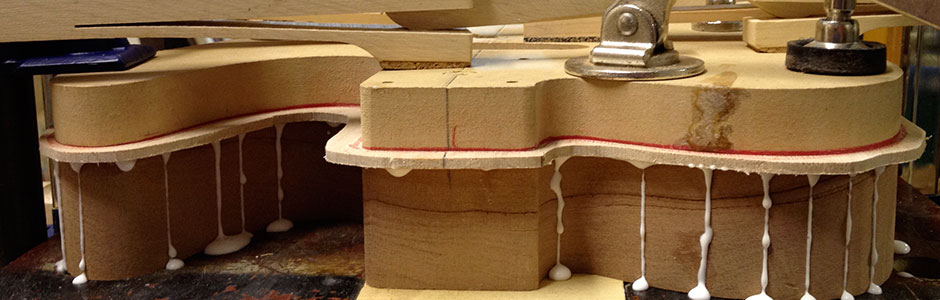

The top was glued up almost a year ago in preparation for the second try at Whit's guitar. The back was sanded down to 3/16" a few weeks ago. Here's a gallery of the steps that go into getting a back ready.

First, the edges need to be trued up so that the two book-matched halves meet at a straight line and that the edges are at compatible angles. You want a 90-degree angle and a long edge that runs parallel to the wood grain. This little jig (above) that the padauk back boards are laying on is called a shooting board and is designed to hold the back (and top) so that the plane can put

The top was glued up almost a year ago in preparation for the second try at Whit's guitar. The back was sanded down to 3/16" a few weeks ago. Here's a gallery of the steps that go into getting a back ready.

First, the edges need to be trued up so that the two book-matched halves meet at a straight line and that the edges are at compatible angles. You want a 90-degree angle and a long edge that runs parallel to the wood grain. This little jig (above) that the padauk back boards are laying on is called a shooting board and is designed to hold the back (and top) so that the plane can put